A pioneer

in engineering solutions

for over 40 years

Thermosystems is a trusted name in South India specializing in the design and manufacture of electrically heated and controlled ovens, furnaces, and custom-engineered electromechanical systems.

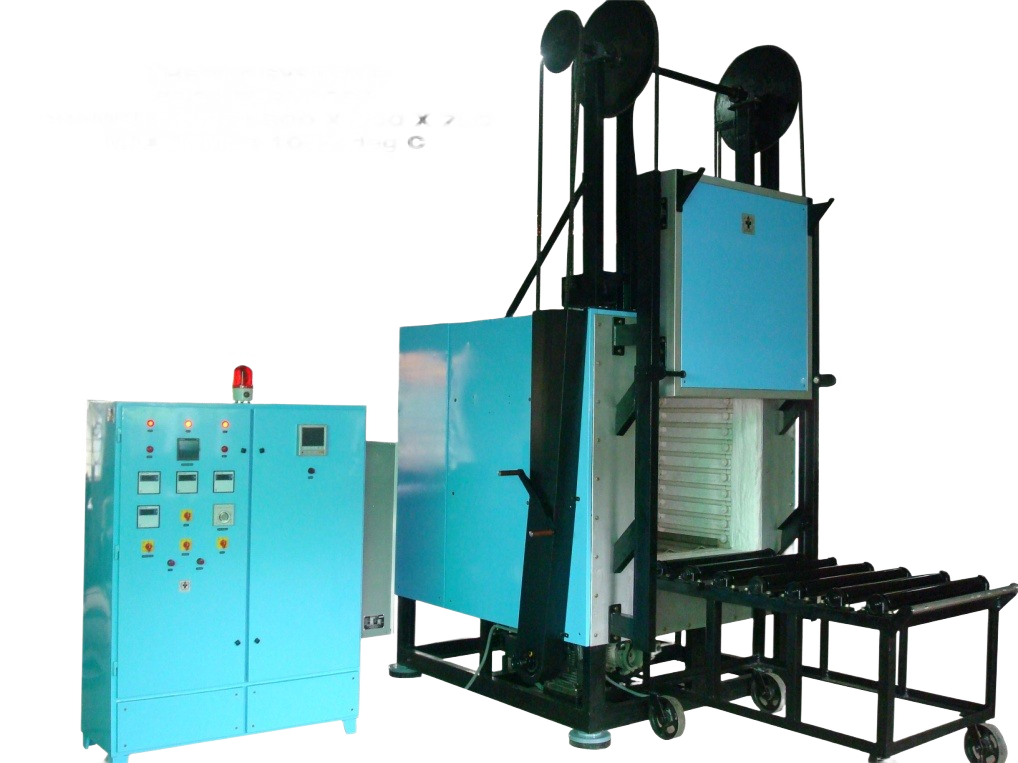

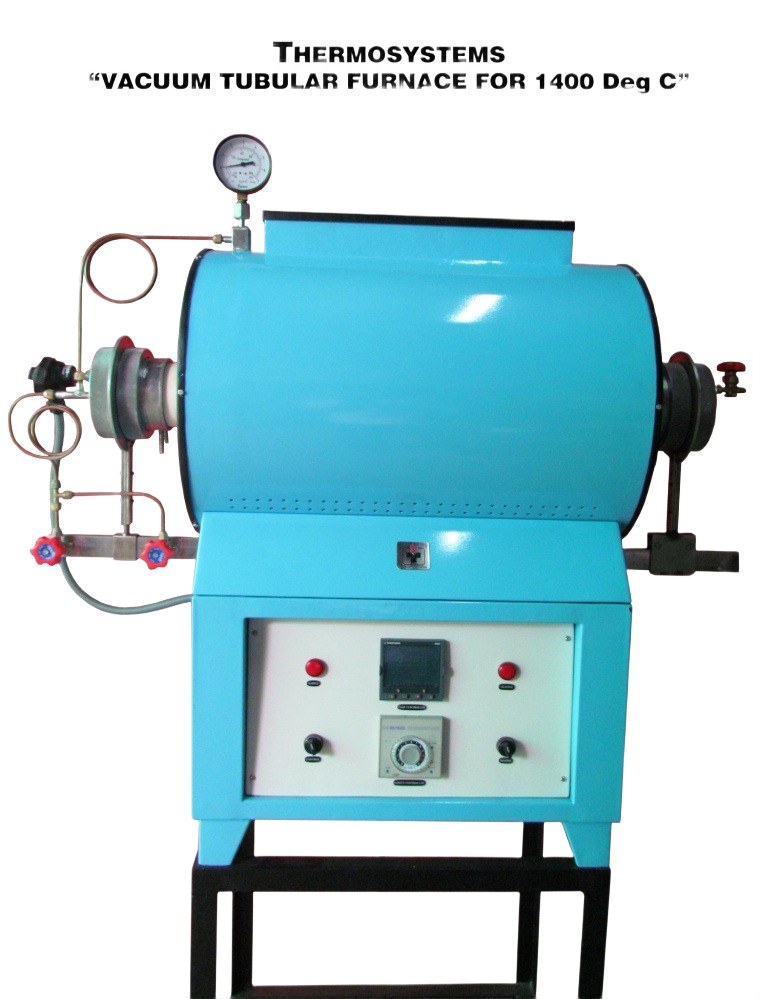

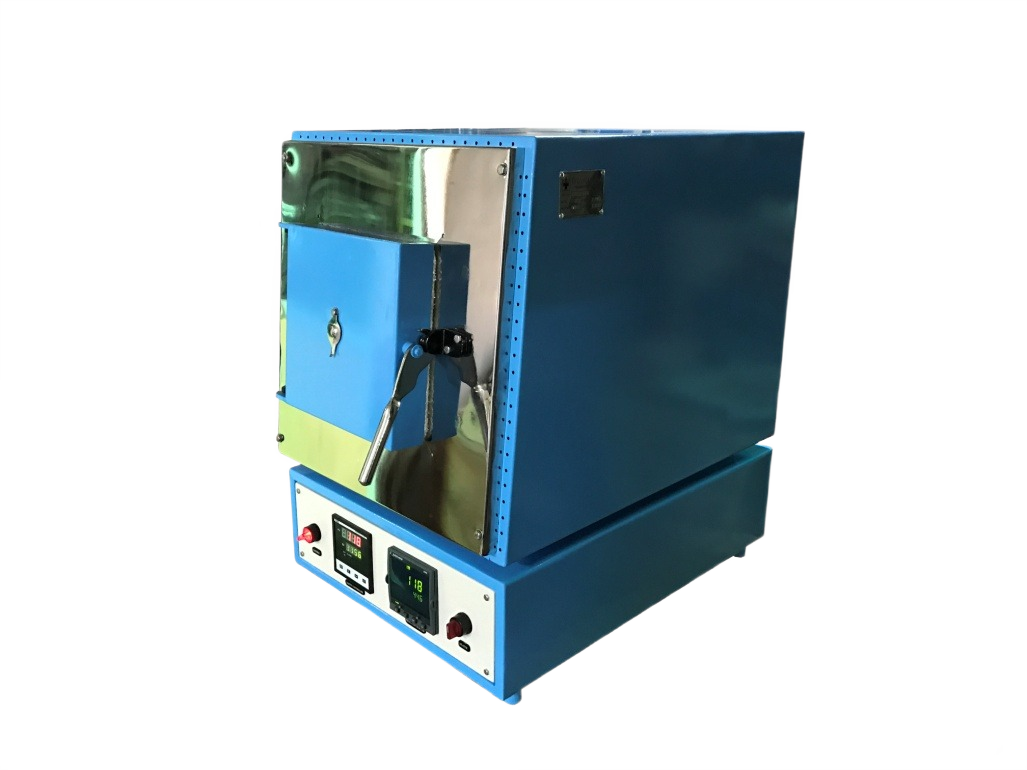

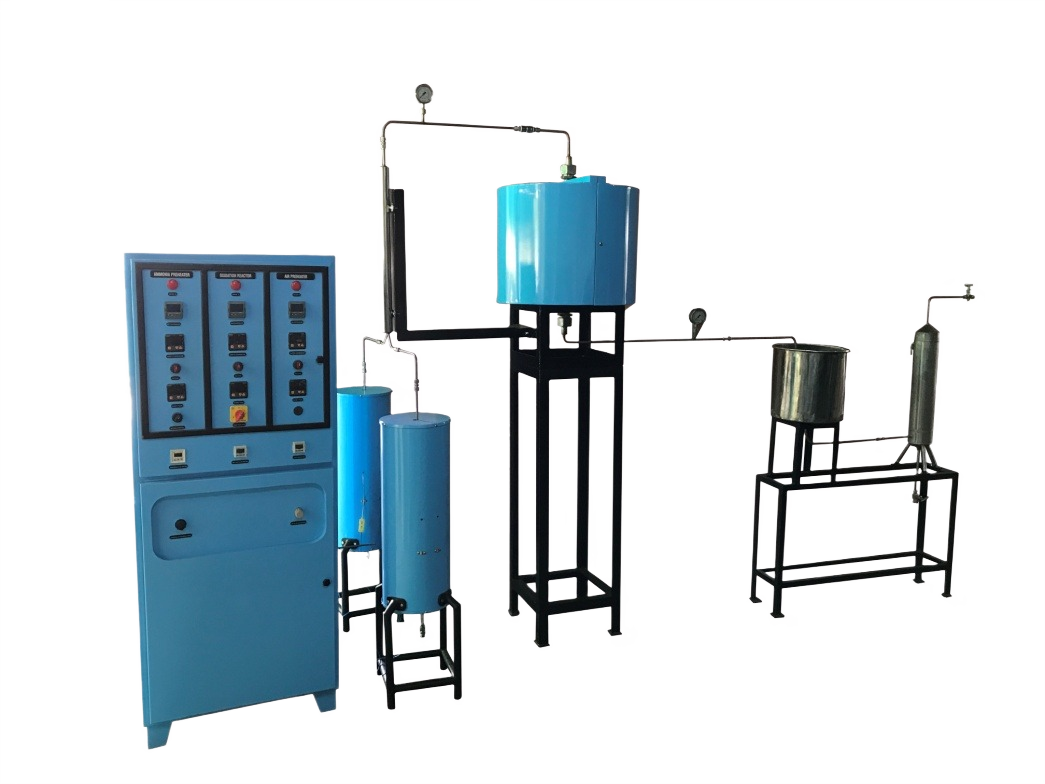

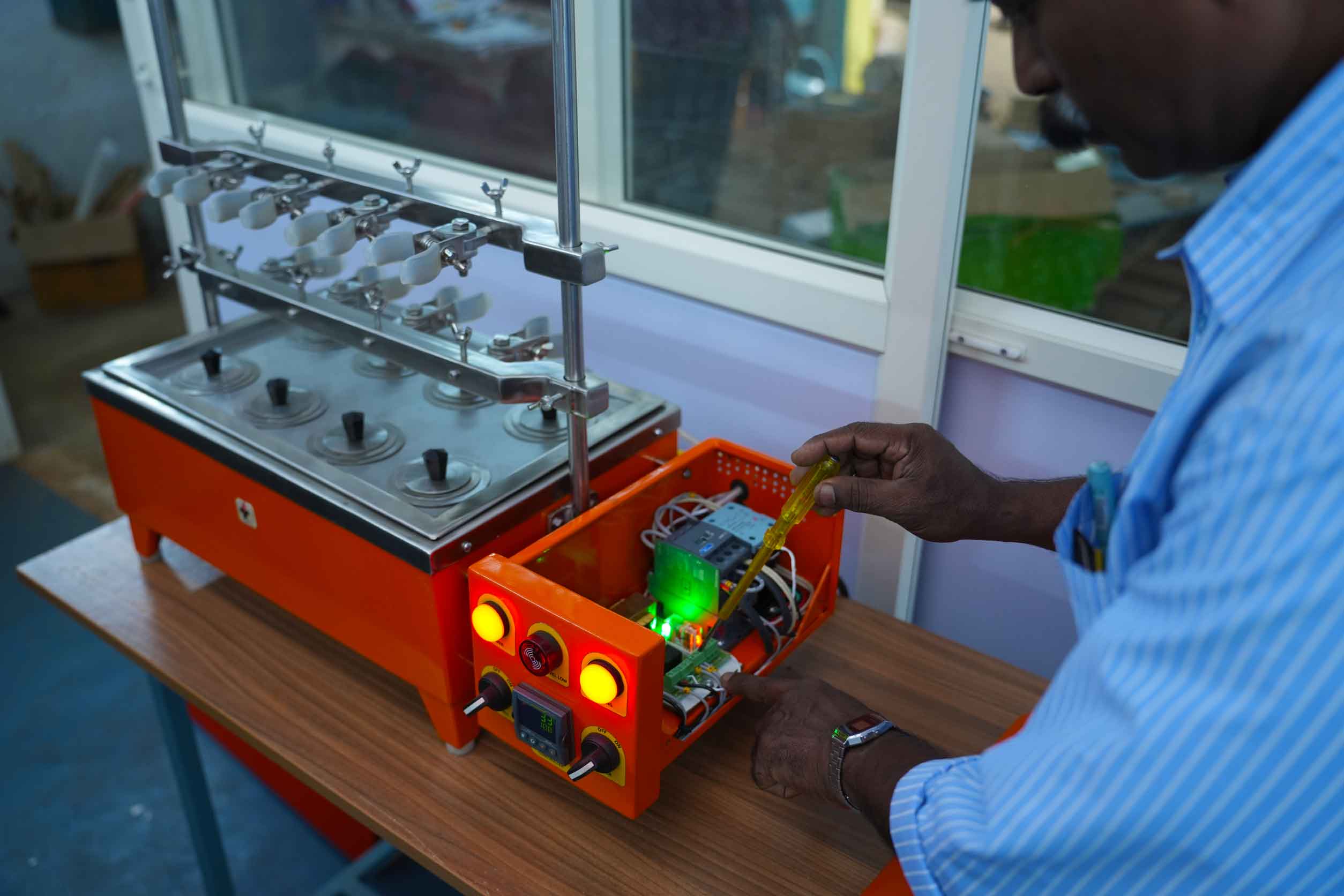

Precision

-Engineered Furnaces &

Industrial Ovens

Thermosystems is a trusted name in South India specializing in the design and manufacture of electrically heated and controlled ovens, furnaces, and custom-engineered electromechanical systems.

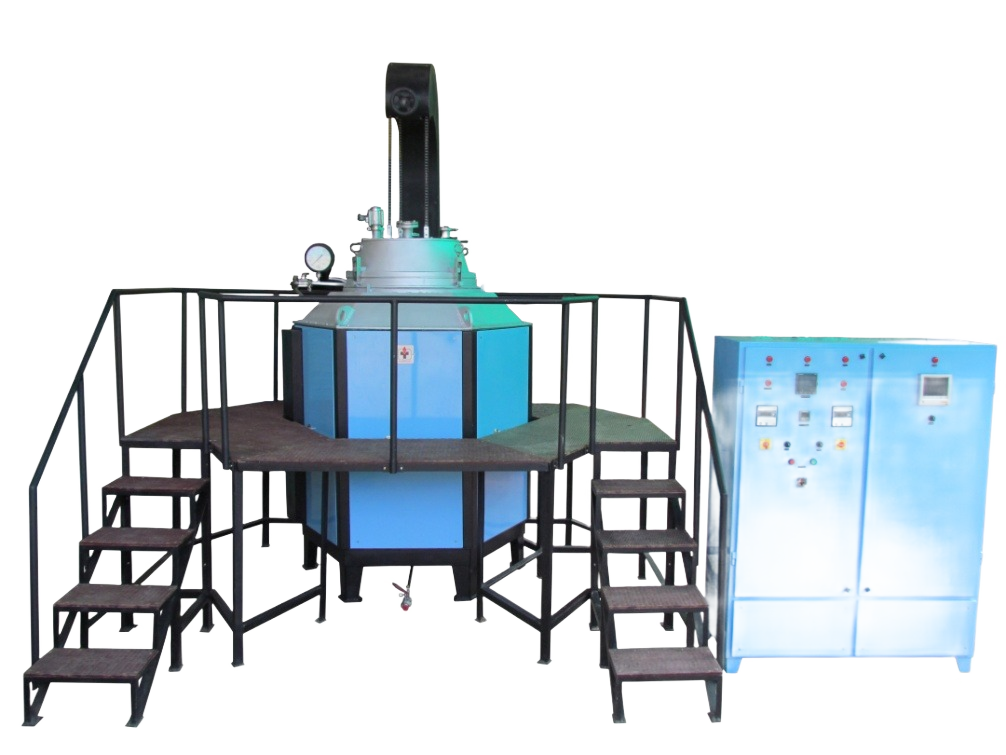

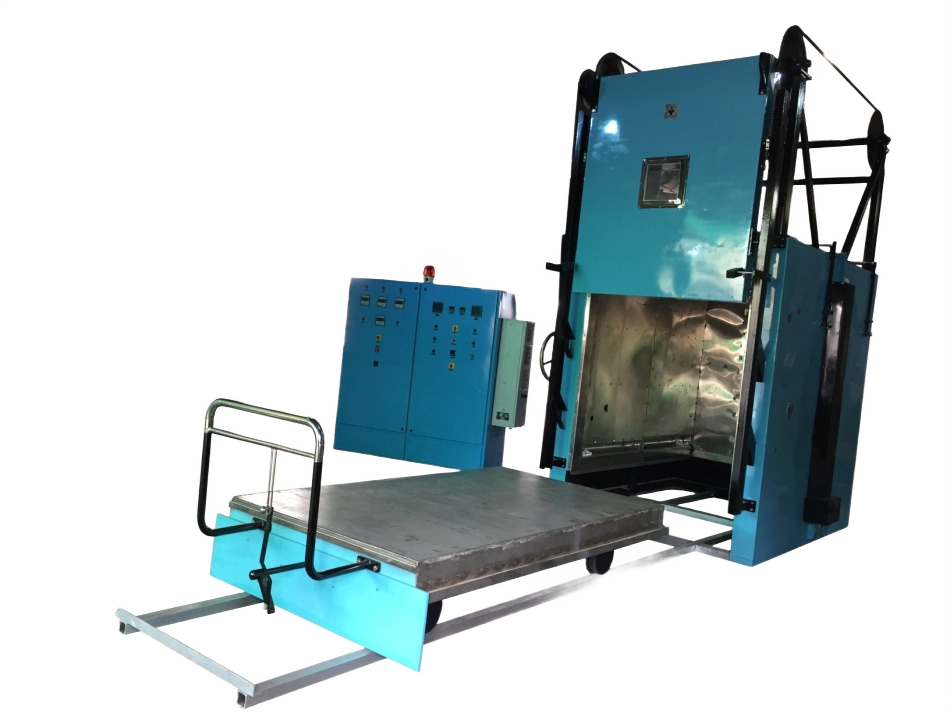

Advanced

Mechanical Design for

Complex Applications

Thermosystems is a trusted name in South India specializing in the design and manufacture of electrically heated and controlled ovens, furnaces, and custom-engineered electromechanical systems.

Engineering

the Future of

Industrial Automation

Thermosystems is a trusted name in South India specializing in the design and manufacture of electrically heated and controlled ovens, furnaces, and custom-engineered electromechanical systems.

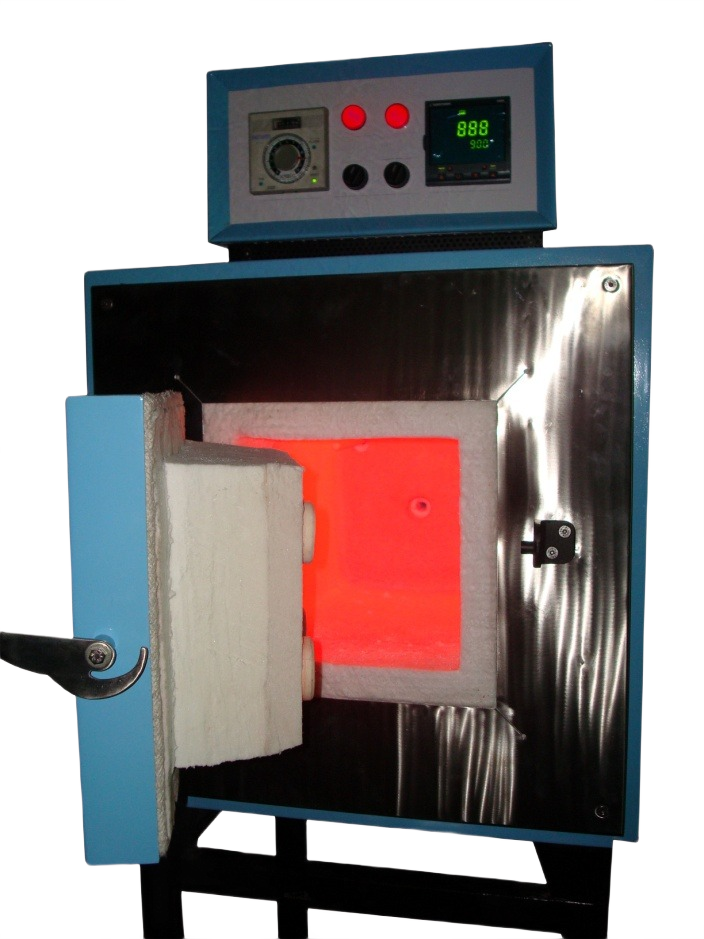

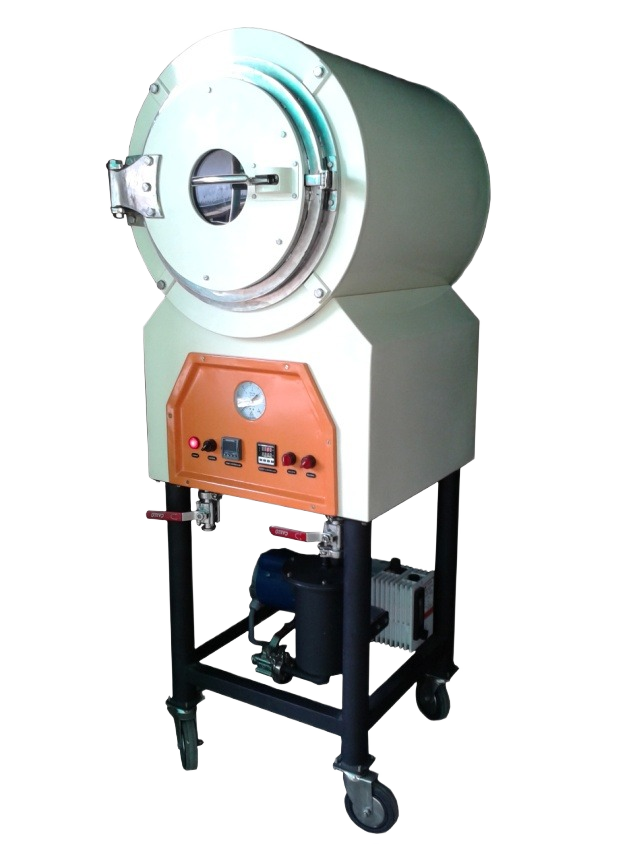

Precision

Testing. Reliable

Evaluation

Thermosystems is a trusted name in South India specializing in the design and manufacture of electrically heated and controlled ovens, furnaces, and custom-engineered electromechanical systems.